Engineering developments of the AEMC department

Laboratory 408. “Laboratory of Conversion Technology” Engineering developments performed by students of the circle “Potential”

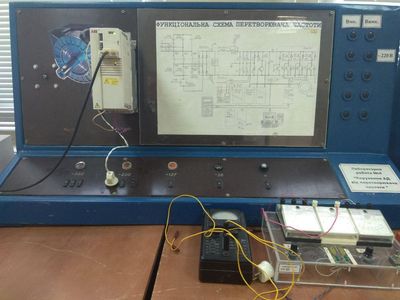

The stand of research of modes of the electric motor at management from the frequency converter

ABB’s Drive Window Light (DWL 2) software on a personal computer is used to control the motor.

The DWL 2 program is designed for frequency converters of types ACS140… ACS400 and DCS400 and provides functions:

- electric drive control;

- the actual condition of the connected electric drive;

- editing the parameters of the electric drive;

- save / load frequency converter parameters from a file;

- copying / restoring the parameters of the electric drive;

- autonomous programming of converter parameters;

- graphic control of electric drive signals;

- numerical control of electric drive signals;

- function for jump response tests.

Communication between the electric drive and the computer is carried out through the RS232 port using the state panel of the electric drive which contains the following points: - device type and node number;

- remote control of the electric drive;

- work / stop;

- direction of rotation (straight or reverse);

- device status, warning, or malfunction.

The stand provides control of the following parameters: - output frequency, Hz;

- current, A;

- power, kW;

- speed, vol. in min

The stand also allows you to take oscillograms using the “Monitor” window, the screen displays graphs of changes in controlled parameters during operation of the electric drive.

The stand of check of serviceability of elements of the frequency converter

On the boards of the stand there are nodes of the circuit of the electric power part of the frequency converter:

– three-phase bridge rectifier; power IGBT transistors with reverse diodes of stand-alone voltage inverter;

– elements of the filter smoothing low-frequency ripple of the rectified voltage, circuits of limiting the charge current of the smoothing capacitor;

– filter elements that smooth out high-frequency oscillations to ensure the electromagnetic compatibility of the frequency converter with the network to reduce the impact of high-frequency interference when switching the power switches of the inverter to the mains;

– elements of electromagnetic compatibility of the frequency converter with the motor to reduce overvoltage on the stator of the motor in the presence of a “long” cable. Checking the serviceability of the elements is carried out using measuring instruments.

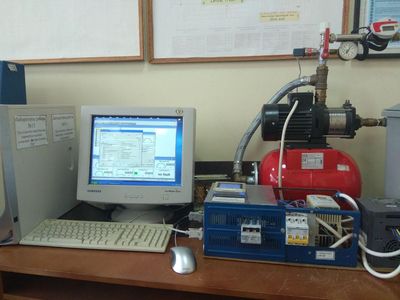

Installation for research of power modes of pump installation with use of the frequency converter

| Made on the basis of an automated water supply station with a Grundfos pump. Automation is carried out by means of the Lenze frequency converter with use of the pressure sensor and work consists in control and maintenance of the set pressure in the pressure head pipeline. The frequency converter has a built-in Pi-regulator, the input of which is supplied with an internal task signal, as well as a signal of the pressure feedback circuit, implemented using a pressure sensor from Danfoss. To measure the flow of the pump, an Actaris flowmeter is installed at its outlet. It also allows you to measure the temperature at the inlet and outlet of the pump. Measurement of electric parameters is carried out by means of the measuring instrument of parameters of the Socomec Diris A40 network that allows to control phase and linear voltages, currents, power, power factor, etc. parameters. |

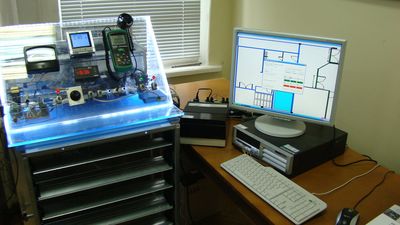

Installation for research of power modes of the fan installation with the valve engine of the EC series of EBMPAPST firm

The valve electric drive is a universal means of electromechanical energy conversion and automation of technological processes. To use the interface of the control and monitoring program of the fan with electronic switching LISA (Low cost Information System for Air handling applications), the fan unit is connected to a computer by means of an interface converter type RS-232 / RS-485. The unit can operate in refrigerator mode, the fan lowers the temperature to a set point, reaching which it turns off. In the heater mode, the temperature rises to the set point, after which the fan also turns off. The pressure sensor gives the difference between the signals from the pressure at the inlet of the fan unit and at the outlet of the diffuser, the fan tends to create a vacuum determined by the setpoint.

Installation for research of energy-efficient modes of the asynchronous electric drive with use of semiconductor converters

The installation provides monitoring and visualization of the main parameters of the asynchronous electric drive, necessary for calculation of energy indicators, to investigate modes of operation of electric drive systems “Frequency converter – asynchronous electric motor”, “Soft start device – asynchronous electric motor” and to estimate energy efficiency, to define their energy efficiency . It also allows you to conduct experimental studies and assess the negative impact of distortions in the shape of current and voltage on the power supply using semiconductor converters.

Laboratory 413 “Automation of technological processes”. Engineering developments were created by Kulakovsky L.Ya., Manuilov VD, Dubovik VG

Two-position microprocessor control system for process parameters

The response of the two-position regulator to the influence of the disturbing factor and the quality of the control indicators in the process of automatic control is investigated at the installation. The investigated installation includes an eight-channel universal measuring instrument-regulator TPM-138, thermocouples of resistance that record the change of temperature, control objects – fan and heater (TEN), SCADA system for real-time simulation process control, installed on PC.

The temperature control in technological processes was implemented at the stand. To achieve the required temperature level at low temperature, the TPM-138 controller turns on the heating element, which heats the ambient temperature, and at high temperature – the air cooling fan. It is possible to control the values of temperatures in real time using the SCADA system.

System of automatic temperature control in heating systems with supply ventilation by means of the TPM-33 microprocessor controller

The heater heats the system when the system is put into operation and the supply air temperature is regulated. The stand includes input temperature sensors, microprocessor controller TPM-33, automatic shut-off and control valve (KZR) Danfoss Socla with electric drive AM-230-2 Belimo. KZR automatically regulates thermal processes in the system by changing the capacity of the valve. KZR belongs to the three-position executive mechanisms, which takes the value of “more” opens, “less” closes and the value of “stop”.

When operating as part of the system, the TPM33 device controls the temperature of the outside (T outside ) and supply air (T ext . ), As well as the temperature of the return water (T source ), which it returns to the thermal power plant, with the help of input transducers . According to the results of temperature control and interrogation of sensors TRM33 controls the operation of the fan and blinds that supply air, as well as regulates the position (KZR), ensuring the automatic performance of the following functions.

System of management of modes of technological accounting of production

The installation allows to simulate the modes of the technological process of counting the number of products on the production line. Production development includes a three-phase asynchronous electric motor with single-phase switching, a pulse counter SI8, a photo sensor type PA18CSD01NA and an inductive sensor type IA12DSN04NE, which allow to read pulses from the labels on the working body of the installation in the form of a tape.

The laboratory stand allows to carry out programming and parameterization of the counter of impulses, research of modes of its work and features of functioning for various technological tasks. With the help of a photo sensor, the specified number of units of finished products is counted. the inductive sensor generates pulses at the input of the pulse counter, which allows you to count the set value of the length of the tape. Along the length of the tape fixed by the inductive sensor, the calculation of the number of goods passing through the tape is performed and when the required amount is reached, a signal is given to turn off the motor and stop the receipt of goods.

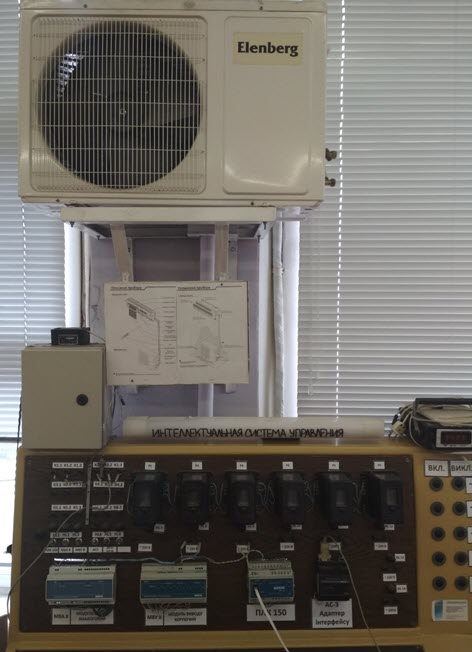

Climate control systems for general purpose facilities based on PLC – 150

The installation allows to carry out simulation regulation of climatic process inside greenhouses for cultivation of various crops. According to the required humidity and temperature regime of growing vegetables or mushrooms, the control program of the logic controller PLK-150 is programmed. Temperature and humidity are recorded by the appropriate sensors TSM100 and DV-01. The commands for setting the required modes come from the programmable controller to the heating element of the heating element or the Elenberg air conditioner to increase or decrease the temperature inside the greenhouse. The humidity of the Vitek humidifier is also regulated.

The installation includes a SCADA system with a program to visualize the parameters of the greenhouse in the Trace Mode environment. Therefore, the greenhouse climate control program has a visual part to simplify process control and management. The operator control panel includes 3 sectors:

- room temperature control;

- humidity control in the room;

- soil temperature control.

Each sector has a “Value” field that displays the current temperature (or humidity) value obtained from the sensors. All values are entered by default for 3 types of greenhouses. Next is a graphical value indicator to facilitate the perception of messages, and indicators that show in which mode the controller is currently.